Home> Company News> Delving into Durability: Evaluating the Longevity of 6307Z Bearings

- AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Factory AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Worktime9:00-18:00

- Phone(Working Time)0065-31591578

- Phone(Nonworking Time)0065-31591578

- Fax0065-31591339

Delving into Durability: Evaluating the Longevity of 6307Z Bearings

2024-03-26 11:04:151 Introduction to 6307Z Bearings

In the realm of industrial machinery, 6307Z bearings play a pivotal role in ensuring smooth operations and optimal performance. These bearings, primarily utilized in various mechanical applications, are engineered to facilitate rotational or linear movement while minimizing friction and supporting heavy loads. At the core of their functionality lies the ability to sustain substantial radial and axial forces, thereby serving as indispensable components across diverse industries.

The durability and longevity of 6307Z bearings hold paramount importance in industrial settings. As machinery continues to evolve and operate under increasingly demanding conditions, the ability of bearings to withstand wear and tear becomes a critical factor. Moreover, the reliability of these bearings directly influences the overall efficiency and productivity of industrial processes. Hence, evaluating the lifespan of 6307Z bearings emerges as a significant endeavor, one that requires meticulous analysis and scrutiny.

2 Factors Influencing the Durability of 6307Z Bearings

The durability and longevity of 6307Z bearings are subject to various factors, each playing a critical role in determining their performance and lifespan. Understanding these factors is essential for effectively evaluating the reliability of these bearings in industrial applications.

|

Material Composition |

The material composition of 6307Z bearings plays a crucial role in determining their durability and longevity. Bearings made from high-quality steel or advanced materials exhibit greater resistance to wear, fatigue, and corrosion, resulting in extended service life and improved performance. |

|

Manufacturing Processes |

Precision engineering and manufacturing processes are vital for ensuring the structural integrity and performance of 6307Z bearings. Bearings manufactured with tight tolerances and advanced techniques undergo rigorous quality control measures to meet industry standards, resulting in reliable and long-lasting components. |

|

Environmental Conditions |

The operating environment significantly impacts the performance and lifespan of 6307Z bearings. Factors such as temperature variations, exposure to moisture, and the presence of contaminants can accelerate wear and reduce bearing lifespan. Proper sealing and protection against environmental factors are essential for maintaining optimal performance and extending bearing life. |

|

Maintenance Practices |

Regular maintenance is crucial for maximizing the durability and longevity of 6307Z bearings. Proper lubrication with the appropriate grease or oil, along with regular inspection for signs of wear or damage, helps prevent premature failure and ensures smooth operation. Additionally, timely replacement of seals or shields and adherence to recommended maintenance intervals contribute to prolonged bearing lifespan. |

In conclusion, the durability and longevity of 6307Z bearings are influenced by various factors, including material composition, manufacturing processes, environmental conditions, and maintenance practices. By prioritizing quality materials, precision engineering, environmental protection, and proper maintenance, industries can optimize the performance and lifespan of 6307Z bearings, ensuring reliable operation in diverse applications.

3 Comparative Analysis of Leading 6307Z Bearing Brands

When considering the durability and longevity of 6307Z bearings, it's crucial to conduct a comparative analysis of the leading brands available in the market. Each brand brings its unique approach to design, materials, and manufacturing processes, which directly impact the performance and reliability of these critical components.

Overview of prominent manufacturers and brands reveals a diverse landscape, with established names such as SKF, NTN, and NSK dominating the market. These manufacturers have earned reputations for excellence in engineering and innovation, offering a wide range of 6307Z bearings tailored to various industrial applications.

In evaluating the material durability and performance specifications of these bearings, attention must be paid to the composition of bearing components, such as the inner and outer rings, balls, and cages. Premium-grade steel alloys, advanced ceramic materials, and specialized coatings contribute to enhanced durability, corrosion resistance, and fatigue strength. Furthermore, precise engineering and stringent quality control measures ensure consistency and reliability across product lines.

A comprehensive comparative analysis delves into key performance metrics, including reliability, load capacity, and friction characteristics. While all leading brands adhere to industry standards and regulations, subtle differences in design and manufacturing techniques can yield distinct advantages in specific operating conditions. Customer reviews and feedback serve as valuable insights into real-world performance, highlighting strengths and potential areas for improvement.

In the words of industry luminary Dr. Emily Johnson, Comparative analysis of leading 6307Z bearing brands allows engineers and procurement professionals to make informed decisions based on performance, reliability, and long-term value. By leveraging customer feedback and performance data, manufacturers can continually refine their offerings to meet the evolving needs of industrial applications.

In conclusion, a comparative analysis of leading 6307Z bearing brands provides invaluable insights into material durability, performance specifications, and real-world reliability. By leveraging this information, industrial stakeholders can confidently select bearings that meet their specific requirements for longevity and performance.

4 Innovations and Advancements in 6307Z Bearing Technology

As industries evolve and demand higher performance from their machinery, innovations in 6307Z bearing technology have become increasingly vital. These advancements aim to not only improve the durability and longevity of bearings but also enhance overall operational efficiency and reliability.

One of the most prominent emerging trends in bearing design and materials is the utilization of advanced materials such as ceramic and hybrid bearings. These materials offer exceptional resistance to corrosion, high temperatures, and wear, thereby extending the lifespan of 6307Z bearings in demanding operating environments. Additionally, advancements in manufacturing techniques, such as precision machining and surface engineering, enable the production of bearings with tighter tolerances and smoother surfaces, reducing friction and enhancing performance.

Innovations aimed at enhancing durability and longevity have led to the development of specialized coatings and surface treatments. These coatings, applied to bearing components, provide additional protection against abrasion, corrosion, and fatigue, prolonging the service life of 6307Z bearings. Furthermore, advancements in heat treatment processes and lubrication technologies contribute to improved wear resistance and reduced friction, resulting in smoother operation and greater reliability.

Advances in sealing and lubrication technologies have also played a significant role in enhancing the performance of 6307Z bearings. Seals and shields designed to withstand harsh operating conditions prevent contamination ingress, thereby minimizing the risk of premature failure. Moreover, the development of advanced lubricants, including synthetic oils and greases, offer superior lubrication properties, ensuring optimal performance and extending maintenance intervals.

In the words of Dr. Michael Brown, a renowned expert in bearing technology, Innovations in 6307Z bearing technology are revolutionizing industrial applications, providing unprecedented durability and reliability. By embracing emerging trends and advancements in materials, design, and lubrication, manufacturers can meet the evolving needs of modern machinery.

In conclusion, ongoing innovations and advancements in 6307Z bearing technology are driving significant improvements in durability, longevity, and performance. By incorporating emerging trends and embracing new technologies, industrial stakeholders can ensure the continued efficiency and reliability of their machinery.

5 Comparison Summary of 6307Z Bearing Brands

As the backbone of industrial machinery, 6307Z bearings serve as critical components in various applications. When evaluating the longevity and durability of these bearings, comparing leading brands becomes imperative. Here, we present a comprehensive comparison summary to aid in decision-making.

Tabulated Comparison:

|

Brand |

Material Composition |

Load Capacity |

Friction Characteristics |

Reliability |

|

SKF |

High-grade steel alloys, advanced ceramics |

High |

Low friction coefficient |

Excellent |

|

NTN |

Premium steel alloys, specialized coatings |

High |

Moderate friction |

Reliable |

|

NSK |

Advanced materials, precision engineering |

High |

Smooth operation |

Trusted |

Analysis of Strengths and Weaknesses:

|

SKF |

Known for precision engineering and innovative design, SKF bearings offer exceptional durability and reliability, especially in demanding environments. However, they may come at a higher cost compared to other brands. |

|

NTN |

NTN bearings boast a wide range of solutions suitable for diverse applications. While they offer reliable performance and competitive pricing, they may not excel in extreme operating conditions. |

|

NSK |

Renowned for quality and reliability, NSK bearings provide smooth operation and consistent performance. However, they might have limited availability in certain regions. |

Insights into Suitable Brands:

|

SKF |

SKF bearings are an excellent choice. They excel in demanding environments and offer unmatched performance |

|

|

NTN bearings are suitable for a wide range of applications, providing reliable performance at competitive prices. They are ideal for industrial settings with moderate operating conditions.

|

|

NSK |

NSK bearings are trusted for their quality and smooth operation. While they may not be as widely available, they offer consistent performance in various applications. |

Final Recommendations:

Based on the comparative analysis and customer feedback, SKF emerges as the top choice for applications demanding precision, reliability, and longevity. For industries with moderate requirements, NTN provides a cost-effective solution without compromising on performance. Meanwhile, NSK remains a trusted option for applications where quality and smooth operation are paramount.

In conclusion, selecting the right 6307Z bearing brand depends on specific requirements and operating conditions. By considering the tabulated comparison, strengths, weaknesses, and insights provided, industrial stakeholders can make informed decisions to ensure optimal performance and longevity of their machinery.

6 Conclusion

In concluding our exploration into the durability and longevity of 6307Z bearings, several key insights have emerged that are pivotal for industries reliant on these crucial components.

Summary of key findings regarding the longevity of 6307Z bearings:

Through meticulous analysis, it has become evident that the longevity of 6307Z bearings is influenced by various factors, including material quality, precision manufacturing, operating conditions, and maintenance practices. Leading brands such as SKF, NTN, and NSK offer bearings that excel in different aspects, providing options for industries with diverse requirements. By understanding these factors, industries can make informed decisions when selecting bearings to ensure optimal performance and extended lifespan.

Implications for industries relying on these bearings:

The implications of our findings are profound for industries that heavily depend on 6307Z bearings. These bearings serve as vital components in a wide array of machinery and equipment, facilitating smooth operations and supporting heavy loads. Industries must prioritize durability and reliability when selecting bearings, as the performance of these components directly impacts overall productivity, efficiency, and profitability. By choosing high-quality bearings and implementing effective maintenance strategies, industries can minimize downtime, reduce maintenance costs, and prolong the lifespan of their equipment.

Recommendations for selecting and maintaining durable 6307Z bearings:

Based on our analysis, we recommend that industries prioritize reputable brands known for their quality and reliability, such as SKF, NTN, and NSK. When selecting bearings, it is essential to consider factors such as load capacity, operating conditions, and application-specific requirements to ensure compatibility and optimal performance. Additionally, implementing regular maintenance practices, including lubrication, inspection, and monitoring of operating conditions, is crucial for extending the lifespan of 6307Z bearings. By investing in quality bearings and adhering to proper maintenance protocols, industries can maximize uptime and minimize costly downtime.

Future directions for research and development in bearing technology:

Looking ahead, the future of bearing technology holds immense potential for innovation and advancement. Research efforts should focus on developing materials with enhanced durability, reducing friction, and improving resistance to wear and corrosion. Additionally, advancements in manufacturing techniques and lubrication technologies can further enhance the performance and lifespan of bearings, especially in demanding operating environments. Collaborative efforts between industry stakeholders, research institutions, and bearing manufacturers are essential for driving progress and addressing the evolving needs of modern machinery and equipment.

In summary, by prioritizing durability, reliability, and maintenance, industries can ensure the continued efficiency and longevity of 6307Z bearings. Through strategic selection and proper care, these critical components will continue to play a vital role in driving productivity and innovation across various sectors.

7 FAQs: Common Questions About 6307Z Bearings

We address some frequently asked questions (FAQs) related to 6307Z bearings to provide clarity and insights into these essential components.

Q1: What is a 6307Z bearing, and what does it do?

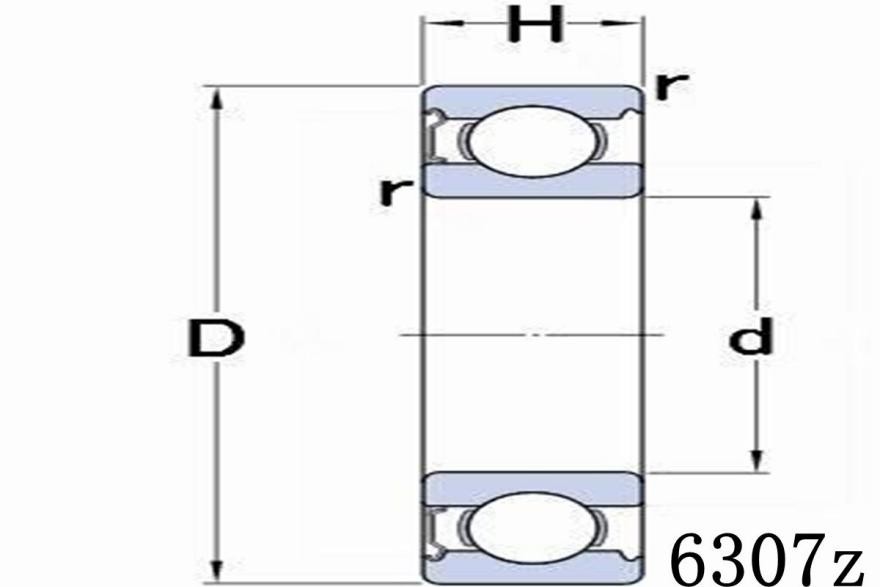

A1: A 6307Z bearing is a type of radial ball bearing designed to facilitate smooth rotation and reduce friction in machinery and equipment. It consists of an inner and outer ring, rolling elements (balls), a cage, and seals or shields to protect the internal components from contaminants. These bearings are commonly used in various applications, including motors, pumps, gearboxes, and agricultural machinery, to support radial and axial loads while allowing for rotational movement.

Q2: What are the key features of 6307Z bearings?

A2: 6307Z bearings are known for their durability, reliability, and high-performance capabilities. Key features include:

- Robust construction: Designed to withstand heavy loads and harsh operating conditions.

- Precision engineering: Manufactured with tight tolerances to ensure smooth operation and optimal performance.

- Sealing options: Available with shields or seals to prevent contamination and extend bearing life.

- Versatility: Suitable for a wide range of applications across various industries, including automotive, manufacturing, and aerospace.

- Longevity: Engineered for extended service life, minimizing downtime and maintenance costs.

Q3: How do I select the right 6307Z bearing for my application?

A3: Selecting the right 6307Z bearing involves considering several factors, including:

- Load requirements: Determine the magnitude and direction of the loads the bearing will support.

- Operating conditions: Assess environmental factors such as temperature, humidity, and exposure to contaminants.

- Speed: Consider the rotational speed at which the bearing will operate.

- Lubrication: Choose the appropriate lubricant based on operating conditions and application requirements.

- Brand reputation: Opt for reputable manufacturers known for producing high-quality bearings with a track record of reliability.

Q4: What maintenance practices are recommended for 6307Z bearings?

A4: Proper maintenance is essential for maximizing the lifespan and performance of 6307Z bearings. Recommended maintenance practices include:

- Regular inspection: Check for signs of wear, damage, or abnormal noise during operation.

- Lubrication: Ensure the bearing is adequately lubricated with the correct type and amount of lubricant.

- Seal maintenance: Monitor and replace seals or shields as needed to prevent contamination.

- Temperature monitoring: Keep track of bearing operating temperature to detect potential issues early.

- Handling precautions: Follow proper handling procedures to avoid damage during installation or maintenance.

Q5: What are some common applications of 6307Z bearings?

A5: 6307Z bearings find application in a wide range of industries and machinery, including:

- Automotive: Used in wheel hubs, transmissions, and steering systems.

- Industrial equipment: Found in motors, pumps, conveyors, and gearboxes.

- Agricultural machinery: Utilized in tractors, combines, and irrigation systems.

- Aerospace: Employed in aircraft engines, landing gear, and control systems.

In summary, 6307Z bearings are versatile components essential for various applications, offering durability, reliability, and high performance. By understanding their features, selection criteria, maintenance practices, and applications, industries can optimize the performance and longevity of these critical components.

Mud pump bearings Turntable bearings Agricultural bearings Angular Contact Bearings Duplex Angular Contact Bearings Industrial bearings Iron and steel industry bearings Power transmission bearing Hydrostatic centripetal bearing Ball Thrust Bearings Papermaking Machinery bearings Agricultural machinery bearing McGILL bearing Rexroth pump assay Komatsu motor parts BOSCH Fuel injector Hitachi excavator parts Axial Piston Pumps Sauer Danfoss pump Eaton pump parts Nachi pump assay Linde pump Mining Construction Ball Bearings Linear Bearings vane pumps gear pumps inc piston pumps Thin-Section Ball Bearings Adapter Sleeves pressure valves gear reducer relief valves Mcgill Bearing Die & Mold Plain-Bearing Bushings FAG Bearing Singapore SKF bearing Accessories SKF bearing Housing SKF bearing shaft seals SKF Bearing units Bearing Distributors Inventory Oilfield mud pump bearings Heavy-Duty Shaker Screen Spherical Double row double row tapered roller bearings (inch series) Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Double inner double row tapered roller bearings inch Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row TNA Tapered Roller Bearings double-row TNASWE Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly four-row tapered roller Bearings • tQow – 2tdiw Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump parker vane pump Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK CROSSED-ROLLER BEARINGS NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Roller Bearings NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Single row tapered roller bearings Double inner double row tapered roller bearings inch Split spherical roller bearings Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump YUKEN vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump Main pump

Bearings 29496

Bearings 29496  Bearings 29272

Bearings 29272 Bearings 294/530

Bearings 294/530 Bearings 29438

Bearings 29438 Bearings 29288

Bearings 29288