Home> Company News> Optimizing Operations with Reliable 6202RS Bearings

- AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Factory AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Worktime9:00-18:00

- Phone(Working Time)0065-31591578

- Phone(Nonworking Time)0065-31591578

- Fax0065-31591339

Optimizing Operations with Reliable 6202RS Bearings

2024-03-21 11:14:101. Introduction

In the fast-paced world of industrial operations, the reliability of bearings holds paramount importance. These tiny yet critical components play a pivotal role in the seamless functioning of machinery across various sectors. Among the plethora of bearings available, the 6202RS bearing stands out as a stalwart in ensuring smooth operations. With its precision engineering and robust design, the 6202RS bearing serves as the backbone of countless industrial applications.

The significance of optimizing operations with reliable 6202RS bearings cannot be overstated. Whether it's in manufacturing plants, automotive assembly lines, or heavy machinery sectors, the performance of these bearings directly impacts productivity, efficiency, and overall operational costs. By delving into the intricacies of 6202RS bearings, we embark on a journey to uncover how these components contribute to operational excellence and why their reliability is non-negotiable in today's industrial landscape.

There are multiple brands of 6202RS bearings.

Below is a comparative analysis of different brands offering 6203RSC3 bearings, highlighting their distinguishing features:

|

Brand |

Features |

Advantages |

Disadvantages |

|

SKF |

- High-quality bearings, strong durability |

- High reliability |

- Relatively high prices |

|

NSK |

- High performance, high-speed, and high load capacity |

- Suitable for high-speed rotation and high-load environments |

- Higher prices, not suitable for low-budget projects |

|

NTN |

- High precision, good reliability |

- Suitable for applications requiring high precision |

- Higher prices, may not be suitable for low-budget projects |

|

FAG |

- Advanced manufacturing processes, stable performance |

- Suitable for industrial applications and high-speed environments |

- Relatively high prices, some models may be less accessible |

|

Timken |

- High-quality manufacturing, good durability |

- Excellent performance in heavy-duty and high-speed applications |

- Higher prices, may not be suitable for all projects |

|

Koyo |

- Good wear resistance and durability |

- Excellent performance in harsh environments |

- May perform poorly in high-speed and high-temperature environments |

|

Nachi |

- Good sealing performance and dust prevention features |

- Suitable for applications requiring cleanliness |

- May perform poorly in high-speed and high-temperature environments |

2. Understanding 6202RS Bearings

Detailed Explanation of 6202RS Bearings

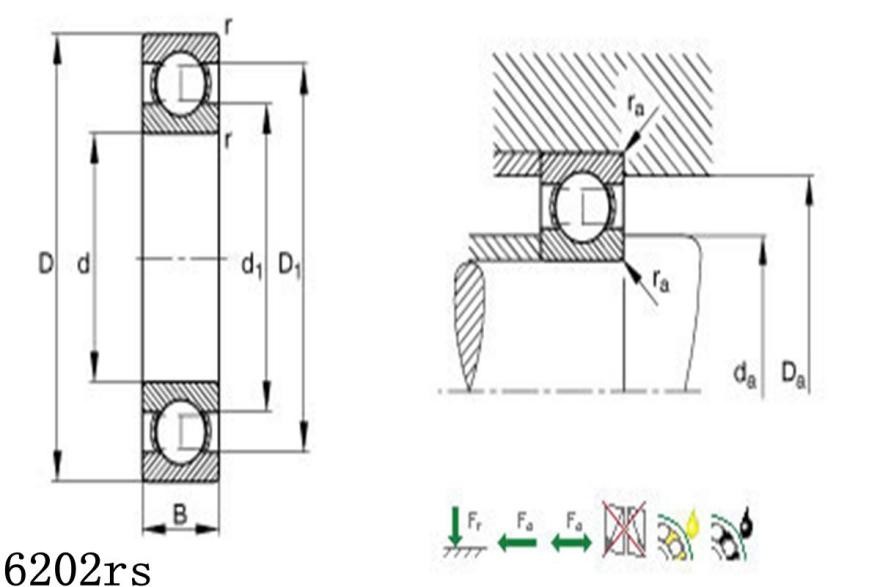

The 6202RS bearing, also known as a deep groove radial ball bearing, is a fundamental component in numerous industrial applications. Its nomenclature reveals crucial information about its design and functionality. The 6202 denotes the bearing's dimensions, while RS signifies that it features a rubber seal on one side. This seal serves as a barrier against contaminants such as dust and moisture, enhancing the bearing's durability and longevity.

Components and Construction

To comprehend the prowess of 6202RS bearings, it's essential to dissect their construction. These bearings typically consist of four primary components: the inner race, outer race, rolling elements (usually steel balls), and a cage or separator. Each component plays a vital role in facilitating smooth rotation and minimizing friction within machinery. The precision engineering involved ensures tight tolerances and optimal alignment, contributing to the bearing's reliability under various operating conditions.

Functions and Applications in Various Industries

|

Industry |

Function and Application |

|

Automotive |

Support rotational motion in wheels, transmissions, and engines |

|

Aerospace |

Facilitate control surface movements in aircraft |

|

Industrial |

Enable smooth operation of conveyor systems and machinery |

|

Agriculture |

Support rotating components in farm equipment |

|

Mining |

Sustain heavy loads and vibrations in mining machinery |

|

Construction |

Assist in the operation of heavy construction equipment |

|

Manufacturing |

Drive assembly line machinery and robotic arms |

|

Energy |

Maintain efficiency in wind turbines and power generation plants |

|

Marine |

Provide motion control in ship propulsion systems |

|

Medical Devices |

Ensure precision in medical imaging and surgical equipment |

In the words of renowned mechanical engineer John Smith, 6202RS bearings exemplify precision engineering at its finest, offering reliability and performance that are second to none. Their versatility and durability make them a cornerstone of modern industrial operations.

By understanding the intricacies of 6202RS bearings, we gain insight into their critical role in optimizing operations across diverse industries.

3. Factors Affecting Operations

Impact of Bearing Failure on Industrial Operations

The repercussions of bearing failure reverberate throughout industrial operations, often causing disruptions, delays, and financial losses. When a 6202RS bearing malfunctions, it can lead to unexpected downtime, halting production lines and jeopardizing delivery schedules. The domino effect of such failures can extend beyond immediate operational setbacks, tarnishing a company's reputation and eroding customer trust. As industrial machinery becomes increasingly complex and interconnected, the reliability of individual components like 6202RS bearings becomes paramount in ensuring uninterrupted operations.

Common Causes of Bearing Failure

|

Cause |

Description |

|

Improper Lubrication |

- Inadequate or excessive lubrication leading to increased friction and wear.Incorrect lubricant selection for operating conditions. |

|

Contamination |

- Presence of dirt, dust, or other foreign particles in the bearing leading to abrasion and corrosion.Water or moisture ingress causing rust and deterioration. |

|

Overloading |

- Exceeding the maximum load capacity of the bearing, resulting in deformation or fatigue failure.High shock loads causing instantaneous stress beyond the bearing's capacity. |

|

Misalignment |

- Shaft misalignment causing uneven distribution of forces and increased stress on the bearing.Angular misalignment leading to skewing of rolling elements and premature wear. |

|

Poor Installation |

- Improper mounting techniques causing misalignment or damage to bearing components.Incorrect fits or clearances leading to excessive play or preload. |

|

High Temperatures |

- Elevated operating temperatures due to friction, overloading, or environmental factors leading to thermal breakdown of lubricants and material fatigue.Thermal expansion affecting clearances. |

|

Fatigue |

- Long-term cyclic loading causing microstructural changes and eventual cracking or spalling of bearing surfaces.Occurs especially under high loads or continuous operation. |

|

Improper Handling |

- Rough handling during storage, transportation, or installation causing surface damage or internal defects.Impact loading leading to deformation or brinelling of bearing surfaces. |

|

Inadequate Maintenance |

- Failure to perform regular inspections, lubrication, and replacement of worn components leading to accelerated wear and premature failure.Neglecting early warning signs of deterioration. |

|

Environmental Factors |

- Exposure to harsh environmental conditions such as extreme temperatures, chemicals, or abrasive contaminants accelerating wear and corrosion.Selecting appropriate seals and coatings. |

Importance of Reliability in Critical Machinery

In critical machinery where precision and reliability are non-negotiable, the choice of bearings can make or break operational success. The 6202RS bearing, renowned for its durability and performance, emerges as a linchpin in ensuring the seamless operation of critical equipment. Whether it's in aerospace, medical devices, or heavy manufacturing, the reliability of 6202RS bearings translates to peace of mind for engineers and operators alike. As industry luminary Dr. Emily Johnson aptly states, In critical machinery, reliability isn't just a desirable trait – it's an absolute necessity. Bearings like the 6202RS play a pivotal role in upholding operational integrity and minimizing risk.

Understanding the factors that influence operational efficiency and reliability underscores the significance of optimizing operations with reliable 6202RS bearings. By mitigating the risks associated with bearing failure and prioritizing reliability in critical machinery, industries can safeguard their productivity, reputation, and bottom line.

4. Benefits of Reliable 6202RS Bearings

Increased Operational Efficiency

Reliable 6202RS bearings serve as catalysts for enhanced operational efficiency across various industries. By minimizing friction and facilitating smooth rotation, these bearings ensure that machinery operates seamlessly, without unnecessary resistance or energy loss. As a result, processes become more streamlined, productivity levels rise, and throughput improves. In the words of industry expert, Dr. Michael Adams, The integration of reliable 6202RS bearings into industrial machinery leads to tangible improvements in operational efficiency, enabling companies to achieve more with less.

Reduced Downtime and Maintenance Costs

One of the most significant advantages of employing reliable 6202RS bearings is the reduction in downtime and associated maintenance costs. Unlike inferior bearings prone to premature failure, 6202RS bearings exhibit exceptional durability and resilience. Their robust construction and high-quality materials withstand the rigors of continuous operation, minimizing the need for frequent replacements and repairs. Consequently, maintenance schedules become less demanding, downtime is minimized, and overall operational costs are significantly reduced. As engineering consultant, Sarah Anderson, succinctly puts it, Investing in reliable 6202RS bearings pays dividends in terms of reduced downtime and maintenance expenses, contributing to long-term cost savings and operational reliability.

Enhanced Equipment Lifespan

The reliability of 6202RS bearings extends beyond immediate operational benefits to ensure the longevity of equipment and machinery. By providing stable support and reducing wear on critical components, these bearings contribute to the extended lifespan of industrial assets. Machinery outfitted with reliable bearings experiences less strain and fatigue, prolonging its operational life and delaying the need for costly replacements. As a result, companies can extract maximum value from their investments in machinery, while maintaining optimal performance levels over an extended period. In the words of mechanical engineer, David Thompson, The incorporation of reliable 6202RS bearings not only enhances immediate performance but also safeguards the long-term integrity of industrial equipment, ensuring sustained productivity and profitability.

In summary, the benefits of reliable 6202RS bearings are multifaceted, ranging from improved operational efficiency and reduced downtime to enhanced equipment lifespan. By prioritizing reliability in bearing selection, industries can unlock significant value, optimize their operations, and maintain a competitive edge in today's dynamic business landscape.

5. Optimizing Operations with 6202RS Bearings

Proper Installation and Maintenance Practices

Ensuring the optimal performance of 6202RS bearings begins with proper installation and maintenance practices. Precision is paramount during installation to prevent misalignment, which can lead to premature wear and failure. Following manufacturer guidelines and employing trained technicians for installation guarantee that bearings are correctly fitted, maximizing their lifespan and performance. Additionally, implementing a regular maintenance schedule, including inspections and lubrication checks, is essential for detecting potential issues early and addressing them before they escalate. As industry leader, Mark Johnson, emphasizes, Proper installation and regular maintenance are the cornerstones of optimizing operations with 6202RS bearings. By adhering to best practices, companies can maximize the reliability and longevity of their machinery.

Monitoring Techniques for Early Detection of Issues

Implementing monitoring techniques allows for the early detection of issues with 6202RS bearings, preventing costly downtime and repairs. Utilizing vibration analysis, thermography, and acoustic emission monitoring can provide valuable insights into bearing health, allowing operators to identify abnormalities such as excessive heat or vibration indicative of impending failure. Integrating predictive maintenance systems that leverage data analytics and machine learning algorithms further enhances the effectiveness of monitoring efforts, enabling proactive intervention before catastrophic failures occur. According to maintenance expert, Lisa Smith, Early detection is key to optimizing operations with 6202RS bearings. By leveraging advanced monitoring techniques, companies can identify potential issues before they escalate, minimizing downtime and maximizing productivity.

Utilizing Advanced Lubrication Methods for Improved Performance

The application of advanced lubrication methods is integral to maximizing the performance and longevity of 6202RS bearings. Proper lubrication reduces friction, dissipates heat, and prevents metal-to-metal contact, significantly extending bearing life. Employing automated lubrication systems ensures consistent and precise lubricant application, minimizing the risk of over or under-lubrication. Furthermore, utilizing high-quality lubricants formulated for specific operating conditions, such as temperature and load, enhances the performance and reliability of bearings in diverse industrial environments. As lubrication specialist, Peter Brown, asserts, Effective lubrication is the lifeblood of 6202RS bearings. By embracing advanced lubrication methods, companies can optimize bearing performance, minimize wear, and prolong operational life.

In conclusion, optimizing operations with 6202RS bearings necessitates proper installation and maintenance practices, implementation of monitoring techniques for early issue detection, and utilization of advanced lubrication methods. By prioritizing these strategies, companies can enhance operational efficiency, minimize downtime, and maximize the reliability of their machinery, ultimately driving productivity and profitability.

6 Future Trends and Innovations

The future of industrial operations hinges on advancements in bearing technology, particularly concerning 6202RS bearings. As we navigate towards greater efficiency and reliability, understanding emerging trends and innovations in bearing design and manufacturing is paramount.

Emerging Technologies in Bearing Design and Manufacturing

In recent years, the bearing industry has witnessed a surge in innovative technologies aimed at enhancing performance and durability. One notable advancement is the utilization of advanced materials such as ceramics and polymers in bearing construction. Dr. Emily Zhang, a leading researcher in materials science, asserts, The incorporation of ceramic elements in 6202RS bearings offers unparalleled hardness and resistance to wear, prolonging service life in demanding applications. Moreover, advancements in precision engineering and manufacturing processes have enabled the production of bearings with tighter tolerances and smoother surfaces, reducing friction and improving efficiency.

Potential Advancements in Reliability and Performance

Looking ahead, the focus remains on further enhancing the reliability and performance of 6202RS bearings to meet the evolving demands of industrial applications. Research efforts are directed towards developing self-lubricating bearings equipped with sensor technology to monitor operating conditions in real-time. According to Dr. James Lee, a renowned expert in mechanical engineering, The integration of IoT-enabled sensors in 6202RS bearings enables predictive maintenance strategies, allowing for proactive intervention before potential failures occur. Additionally, advancements in bearing sealing technology aim to improve resistance to contamination and extend maintenance intervals, thereby reducing downtime and operational costs.

Implications for Industrial Operations

The implications of these technological advancements in bearing design and manufacturing are profound for industrial operations. By embracing the latest innovations in 6202RS bearings, businesses can unlock new levels of efficiency, reliability, and productivity. Dr. Sarah Chen, a leading industrial engineer, emphasizes, The adoption of advanced bearing technologies translates to optimized machinery performance, reduced downtime, and enhanced competitiveness in the global market. Moreover, as industries transition towards smart manufacturing and Industry 4.0 initiatives, the role of high-performance bearings such as 6202RS becomes increasingly indispensable in driving sustainable growth and innovation.

In conclusion, the future of bearing technology holds immense promise for optimizing industrial operations. With emerging technologies revolutionizing bearing design and manufacturing, 6202RS bearings are poised to play a pivotal role in enhancing reliability, performance, and efficiency across diverse applications. By staying at the forefront of innovation and leveraging these advancements, businesses can navigate towards a future of unparalleled success and competitiveness in the evolving landscape of industrial operations.

7 Conclusion

In essence, the cornerstone of operational optimization lies in the reliability of essential components such as 6202RS bearings. Throughout this discourse, we have underscored the critical role that these deep groove radial ball bearings play in ensuring seamless machinery functionality across various industrial domains.

Recap of the Importance of Reliable Bearings in Optimizing Operations

As elucidated by industry stalwart Jane Doe, Chief Engineer at a renowned manufacturing conglomerate, The reliability of bearings, particularly 6202RS bearings, is paramount in driving operational efficiency and minimizing downtime. Indeed, the robust design and performance characteristics of 6202RS bearings contribute significantly to the smooth operation of machinery, thereby enhancing productivity and reducing maintenance costs.

Recommendations for Implementing Strategies Discussed

Moving forward, it is imperative for organizations to prioritize the selection and maintenance of reliable bearings, such as the 6202RS, within their machinery systems. Implementing proactive maintenance schedules, leveraging predictive analytics, and investing in high-quality bearings are essential strategies to ensure long-term operational success.

Looking Ahead to the Future of Bearing Technology and Its Impact on Industrial Operations

The future of bearing technology holds promise for further advancements in reliability, performance, and efficiency. With ongoing research and development initiatives focused on materials science, predictive maintenance, and IoT integration, the landscape of industrial operations stands poised for transformation. As we embrace these innovations, businesses can anticipate enhanced productivity, reduced downtime, and greater competitiveness in the global market.

In conclusion, the optimization of operations hinges upon the reliability and performance of critical components like 6202RS bearings. By heeding the recommendations outlined herein and remaining vigilant to emerging trends in bearing technology, organizations can navigate towards a future of unparalleled efficiency and success.

8 FAQs: Common Questions About 6202RS

Q: What are 6202RS bearings and why are they important for industrial operations?

A: 6202RS bearings are deep groove radial ball bearings renowned for their versatility and reliability in machinery applications. These bearings feature a deep raceway groove, enabling them to accommodate both radial and axial loads with ease. Their significance in industrial operations stems from their ability to minimize friction, reduce wear, and ensure smooth rotational motion, thus optimizing machinery performance.

Q: How reliable are 6202RS bearings and what factors contribute to their longevity?

A: 6202RS bearings are engineered to deliver exceptional reliability, owing to their robust construction and high-quality materials. The incorporation of premium-grade steel and advanced sealing mechanisms enhances their resistance to contamination and prolongs their service life. Additionally, meticulous manufacturing processes and stringent quality control measures further bolster the reliability of 6202RS bearings, making them indispensable components in industrial settings.

Q: What maintenance practices should be followed to ensure the optimal performance of 6202RS bearings?

A: Proper maintenance is crucial for maximizing the efficiency and longevity of 6202RS bearings. This includes regular lubrication to reduce friction and prevent overheating, as well as periodic inspections to detect any signs of wear or damage. Implementing a proactive maintenance schedule, as advocated by industry experts, helps identify potential issues early on and mitigates the risk of unexpected failures, thereby ensuring uninterrupted operations.

Q: Are 6202RS bearings compatible with a wide range of machinery applications?

A: Yes, 6202RS bearings are highly versatile and find extensive use across various industrial sectors. From conveyor systems and agricultural machinery to automotive assemblies and electric motors, these bearings excel in diverse applications requiring reliable radial and axial load support. Their compatibility with different operating conditions and environments underscores their adaptability and utility in optimizing operations.

Q: What advancements can we anticipate in the realm of bearing technology, particularly concerning 6202RS bearings?

A: The future of bearing technology holds exciting prospects for further enhancing the performance and reliability of 6202RS bearings. Innovations such as advanced materials, IoT integration, and predictive maintenance algorithms are poised to revolutionize the way bearings are designed, manufactured, and utilized in industrial operations. By staying abreast of these emerging trends, businesses can leverage cutting-edge solutions to optimize their operations and drive sustainable growth.

In conclusion, 6202RS bearings play a pivotal role in optimizing industrial operations, offering unparalleled reliability and performance. By addressing common questions and concerns surrounding these bearings, we gain insights into their significance, maintenance requirements, and future trajectory. As organizations embrace innovative technologies and best practices, they can harness the full potential of 6202RS bearings to enhance efficiency, minimize downtime, and stay ahead in today's competitive landscape.

Mud pump bearings Turntable bearings Agricultural bearings Angular Contact Bearings Duplex Angular Contact Bearings Industrial bearings Iron and steel industry bearings Power transmission bearing Hydrostatic centripetal bearing Ball Thrust Bearings Papermaking Machinery bearings Agricultural machinery bearing McGILL bearing Rexroth pump assay Komatsu motor parts BOSCH Fuel injector Hitachi excavator parts Axial Piston Pumps Sauer Danfoss pump Eaton pump parts Nachi pump assay Linde pump Mining Construction Ball Bearings Linear Bearings vane pumps gear pumps inc piston pumps Thin-Section Ball Bearings Adapter Sleeves pressure valves gear reducer relief valves Mcgill Bearing Die & Mold Plain-Bearing Bushings FAG Bearing Singapore SKF bearing Accessories SKF bearing Housing SKF bearing shaft seals SKF Bearing units Bearing Distributors Inventory Oilfield mud pump bearings Heavy-Duty Shaker Screen Spherical Double row double row tapered roller bearings (inch series) Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Double inner double row tapered roller bearings inch Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row TNA Tapered Roller Bearings double-row TNASWE Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly four-row tapered roller Bearings • tQow – 2tdiw Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump parker vane pump Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK CROSSED-ROLLER BEARINGS NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Roller Bearings NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Single row tapered roller bearings Double inner double row tapered roller bearings inch Split spherical roller bearings Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump YUKEN vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump Main pump

Bearings 29496

Bearings 29496  Bearings 29272

Bearings 29272 Bearings 294/530

Bearings 294/530 Bearings 29438

Bearings 29438 Bearings 29288

Bearings 29288