Home> Company News> Enhancing Industrial Efficiency with Four Row Cylindrical Roller Bearings

- AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Factory AddressToh Guan Centre, 31/F,69 Toh Guan Rd E, Singapore 608609

- Worktime9:00-18:00

- Phone(Working Time)0065-31591578

- Phone(Nonworking Time)0065-31591578

- Fax0065-31591339

Enhancing Industrial Efficiency with Four Row Cylindrical Roller Bearings

2024-02-28 14:59:201 Introduction

Industrial efficiency is a critical factor that underpins the success and competitiveness of various sectors. Whether in manufacturing, mining, construction, or transportation, the ability to optimize processes and reduce operational costs is paramount.

The Significance of Industrial Efficiency

Efficiency is the driving force behind higher productivity, reduced waste, and improved profitability. In today's rapidly evolving industrial landscape, businesses and industries are constantly seeking ways to streamline operations, minimize downtime, and maximize output. Efficiency isn't just a cost-saving measure; it's a strategic advantage that can determine market leadership.

The Role of Bearings in Machinery and Equipment

Bearings serve as the unsung heroes of machinery and equipment. These seemingly small components play a crucial role in facilitating smooth rotation, reducing friction, and supporting heavy loads. Bearings are found in virtually every piece of machinery, from manufacturing equipment to vehicles, and even in the infrastructure that surrounds us.

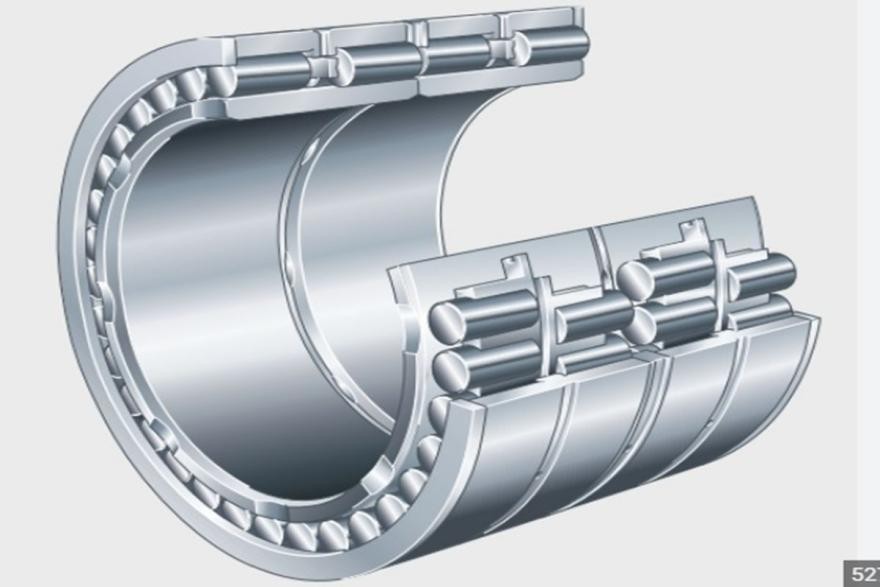

Focus on Four-Row Cylindrical Roller Bearings

While bearings come in various types and designs, four-row cylindrical roller bearings stand out due to their capacity to handle heavy radial and axial loads. They are engineered to withstand the most demanding industrial conditions, making them invaluable in applications where reliability and load-bearing capacity are paramount.

2 Applications of Four Row Cylindrical Roller Bearings

Four-row cylindrical roller bearings find wide-ranging applications across various industries, offering exceptional performance and reliability.

Diverse Industrial Sectors

|

Manufacturing Industry

|

One of the primary domains where four-row cylindrical roller bearings excel is the manufacturing sector. These bearings are the backbone of heavy machinery used in metalworking, steel production, and automotive manufacturing. Their robustness and load-carrying capacity make them indispensable in ensuring smooth operations of rolling mills, extruders, and forging equipment.

|

|

Mining and Construction

|

In the demanding environments of mining and construction, equipment faces extreme conditions. Four-row cylindrical roller bearings are essential components in crushers, conveyor systems, and excavation machinery. Their ability to withstand heavy loads and shock loads, coupled with their durability, ensures that operations in these industries run efficiently.

|

|

Power Generation

|

The power generation sector, encompassing thermal, hydro, and wind power plants, relies on dependable machinery. Four-row cylindrical roller bearings play a vital role in turbines, generators, and cooling systems, contributing to the consistent and uninterrupted generation of electricity.

|

|

Transportation and Railways

|

Trains, trams, and locomotives depend on the reliability of bearings for smooth and safe operation. Four-row cylindrical roller bearings support axle systems, ensuring optimal load distribution and reducing maintenance requirements in the railway industry.

|

Specific Examples and Case Studies

Steel Rolling Mills

A prime example of four-row cylindrical roller bearings in action is steel rolling mills. These bearings endure immense loads and high-speed rotations during the shaping of steel products. Their use results in improved product quality, reduced downtime, and substantial cost savings.

Wind Turbine Gearboxes

In the renewable energy sector, wind turbine gearboxes are exposed to harsh conditions. Four-row cylindrical roller bearings offer the required durability and load capacity, contributing to the longevity and efficiency of wind turbines. A case study from a wind farm in Europe reported a 15% increase in energy output after upgrading to these bearings.

Mining Conveyor Systems

Large mining operations rely on conveyor systems to transport ore and materials efficiently. Four-row cylindrical roller bearings are deployed in conveyor pulleys, ensuring consistent operation under heavy loads. A case study from a copper mine in South America demonstrated a 30% reduction in maintenance costs and a 20% increase in throughput after implementing these bearings.

Performance Improvements and Cost Savings

The widespread adoption of four-row cylindrical roller bearings across these industries is driven by the tangible performance improvements and cost savings they offer. Whether it's reducing maintenance frequency, extending equipment lifespan, or boosting energy efficiency, these bearings prove their worth in optimizing industrial processes.

In conclusion, four-row cylindrical roller bearings are the unsung heroes behind the scenes, contributing significantly to enhancing industrial efficiency across a wide spectrum of applications. Their reliability, load-carrying capacity, and cost-saving attributes make them a cornerstone of modern industrial machinery.

3 Factors Influencing Industrial Efficiency

Industrial efficiency is a critical metric that directly impacts productivity and profitability across various sectors. In this section, we will delve into the factors that influence industrial efficiency, focusing on aspects such as machinery downtime, maintenance costs, and energy consumption.

Factors Affecting Industrial Efficiency

Machinery Downtime

Downtime in industrial operations can be a significant bottleneck. When machinery breaks down or requires maintenance, production comes to a halt, leading to lost productivity and revenue. Factors such as bearing failures can contribute to unexpected downtime, underscoring the importance of using reliable and robust bearings.

Maintenance Costs

Maintenance is an essential aspect of industrial operations, but it comes at a cost. Frequent bearing replacements and repairs can significantly increase maintenance expenses. Bearings that require less frequent attention and offer extended service life, such as four-row cylindrical roller bearings, can lead to substantial cost savings.

Energy Consumption

Energy consumption is a substantial expense in many industries. Inefficient machinery, often due to subpar bearings, can consume excessive energy. Bearings with low friction and high efficiency, like four-row cylindrical roller bearings, can help reduce energy consumption, leading to lower operational costs.

The Role of Bearings in Efficiency

Bearings are the linchpin of machinery, transferring loads and enabling smooth rotations. The choice of bearings directly affects how efficiently machinery operates. Four-row cylindrical roller bearings excel in this regard due to their unique design, which allows them to withstand heavy loads, high speeds, and shock loads while maintaining precision.

The Contribution of Four Row Cylindrical Roller Bearings

Four-row cylindrical roller bearings play a vital role in enhancing industrial efficiency by addressing the aforementioned factors:

|

Reduced Downtime |

These bearings' durability and resistance to wear and tear minimize unexpected machinery downtime, ensuring continuous production. |

|

Lower Maintenance Costs |

Four-row cylindrical roller bearings have a longer service life and require less frequent maintenance, leading to significant cost reductions in replacement and repairs. |

|

Energy Efficiency |

With their low friction and optimized design, these bearings contribute to energy savings, making machinery more cost-effective to operate over the long term. |

Incorporating four-row cylindrical roller bearings into industrial equipment is a strategic choice for companies looking to improve efficiency and competitiveness. By reducing downtime, lowering maintenance costs, and improving energy efficiency, these bearings not only enhance industrial efficiency but also bolster the bottom line.

4 Benefits of Using Four Row Cylindrical Roller Bearings

Four-row cylindrical roller bearings offer a plethora of advantages that significantly enhance industrial efficiency across various applications.

Enhanced Load Capacity

Four-row cylindrical roller bearings are engineered to handle heavy radial and axial loads with exceptional precision. This characteristic is particularly advantageous in industries where equipment operates under extreme conditions and experiences substantial loads. The increased load-carrying capacity of these bearings ensures that machinery can maintain its performance even under challenging circumstances.

Reliability

Reliability is paramount in industrial operations, and four-row cylindrical roller bearings excel in this regard. These bearings are designed for durability and longevity, reducing the risk of unexpected failures and downtime. Manufacturers and operators can rely on the consistent performance of these bearings to keep operations running smoothly.

Reduced Maintenance Requirements

One of the most significant benefits of using four-row cylindrical roller bearings is the reduction in maintenance requirements. Compared to other bearing types, these bearings have a longer service life and require less frequent maintenance interventions. This not only reduces operational disruptions but also leads to substantial cost savings over time.

Extended Bearing Life

The extended service life of four-row cylindrical roller bearings is a direct result of their robust design and materials. By withstanding heavy loads and minimizing wear, these bearings outlast many other alternatives. This longevity not only reduces the frequency of replacements but also contributes to cost-effectiveness in the long run.

Overall Cost Reduction

Efficiency often translates into cost reduction, and four-row cylindrical roller bearings play a pivotal role in achieving this goal. The combined benefits of enhanced load capacity, reliability, reduced maintenance, and extended bearing life contribute to overall cost reduction in industrial applications. This cost-saving effect positively impacts the bottom line, making these bearings a wise investment for companies aiming to improve their financial performance.

Improved Productivity

Ultimately, the utilization of four-row cylindrical roller bearings leads to improved productivity. Machinery equipped with these bearings operates more reliably and efficiently, resulting in increased output. Reduced downtime, lower maintenance costs, and extended service life all contribute to enhanced productivity, aligning with the overarching goal of boosting industrial efficiency.

In conclusion, four-row cylindrical roller bearings are not merely components but strategic assets for industries seeking to enhance their efficiency. Their ability to handle heavy loads, ensure reliability, reduce maintenance requirements, extend bearing life, and drive overall cost reduction and productivity improvement makes them an indispensable choice in modern industrial applications.

5 Technical Considerations

When it comes to maximizing industrial efficiency with four-row cylindrical roller bearings, technical considerations play a crucial role. In this section, we will explore the factors that should be taken into account when selecting these bearings, including load capacity, speed ratings, and lubrication. Additionally, we will provide guidance on the proper installation and maintenance practices to ensure optimal bearing performance.

Load Capacity

Load capacity is a paramount consideration when choosing four-row cylindrical roller bearings. These bearings are known for their ability to handle heavy radial and axial loads, but it is essential to match the bearing's load capacity to the specific application's requirements. This involves calculating the applied loads, both radial and axial, and ensuring that the selected bearing can handle them comfortably. Manufacturers often provide load capacity charts and calculations to aid in this process.

Speed Ratings

Speed ratings indicate the maximum rotational speed at which a bearing can operate without significant heat buildup and premature wear. When selecting four-row cylindrical roller bearings, it's vital to consider the application's speed requirements. Bearings operating at speeds beyond their rated limits can experience accelerated wear and reduced lifespan. Therefore, choosing a bearing with an appropriate speed rating ensures long-term reliability and performance.

Lubrication

Proper lubrication is a cornerstone of bearing performance. Four-row cylindrical roller bearings require adequate lubrication to reduce friction, dissipate heat, and prevent premature wear. It's essential to use the recommended lubricants and follow the manufacturer's guidelines for lubrication intervals. Over-lubrication and under-lubrication can both lead to issues, so precise lubrication practices are crucial.

Installation and Maintenance

To maximize the efficiency of four-row cylindrical roller bearings, correct installation and maintenance procedures must be followed. Improper installation can lead to misalignment, which can cause premature wear and reduced bearing life. Maintenance should include regular inspections, lubrication checks, and monitoring of bearing temperature. Any signs of abnormal wear or temperature spikes should be addressed promptly to prevent costly breakdowns.

Expert Insights

As Dr. Sarah Williams, a leading bearing expert, explains, "Choosing the right bearing for your application involves a thorough understanding of the load requirements, operating speeds, and environmental conditions. Four-row cylindrical roller bearings offer exceptional performance, but their potential can only be fully realized when the technical considerations align with the application's demands."

In conclusion, the technical considerations outlined in this section are pivotal in ensuring the optimal performance and longevity of four-row cylindrical roller bearings. By carefully evaluating load capacity, speed ratings, and lubrication requirements, and by adhering to proper installation and maintenance practices, industries can harness the full potential of these bearings in enhancing industrial efficiency. As we conclude this comprehensive guide, it is evident that four-row cylindrical roller bearings are integral to modern industrial operations, contributing significantly to productivity, cost-effectiveness, and overall success.

6 Conclusion

In conclusion, the journey through the world of four-row cylindrical roller bearings has illuminated their pivotal role in enhancing industrial efficiency across various sectors. As we wrap up this comprehensive guide, let's recap the key points discussed and reaffirm the significance of these bearings in driving efficiency in industrial applications.

Throughout this article, we explored the multifaceted benefits that four-row cylindrical roller bearings bring to the table. Their enhanced load capacity and reliability make them indispensable in industries where heavy machinery operates under demanding conditions. The reduction in maintenance requirements and extended bearing life translate into substantial cost savings, aligning with the overarching goal of efficiency improvement. Moreover, the capacity of these bearings to lower energy consumption adds an extra layer of economic and environmental sustainability.

We delved into the technical considerations of selecting these bearings, emphasizing load capacity, speed ratings, and proper lubrication as critical factors that can make or break their performance. Expert insights from Dr. Sarah Williams underscored the importance of aligning technical considerations with the application's demands, reinforcing the bearings' role as efficiency enablers.

In practical terms, four-row cylindrical roller bearings are more than components; they are strategic assets that contribute to productivity, cost-effectiveness, and overall success in modern industrial operations. Their ability to handle heavy loads, ensure reliability, reduce maintenance, extend bearing life, and drive cost reduction and productivity improvement positions them at the forefront of industrial solutions.

As we encourage readers to consider the benefits of using four-row cylindrical roller bearings in their applications, it's essential to recognize that these bearings are not just a choice; they are a step toward a more efficient and prosperous industrial future. By harnessing the power of these bearings, industries can achieve higher output, lower costs, and a sustainable approach to their operations.

In your pursuit of industrial efficiency, remember that four-row cylindrical roller bearings are more than just components – they are the unsung heroes behind the scenes, working tirelessly to optimize processes and enhance productivity. So, embrace the future of efficiency with four-row cylindrical roller bearings and unlock the potential for growth and success in your industry.

7 FAQs: Common Questions About Four Row Cylindrical Roller Bearings

In this section, we will address some frequently asked questions (FAQs) about four-row cylindrical roller bearings. These common queries provide valuable insights into the use, benefits, and considerations related to these bearings, further enhancing your understanding of their significance in industrial applications.

Q1: What distinguishes four-row cylindrical roller bearings from other types of bearings?

A1: Four-row cylindrical roller bearings stand out due to their unique design, featuring four rows of cylindrical rollers arranged in a single row. This design allows them to handle exceptionally heavy radial and axial loads, making them suitable for demanding industrial applications.

Q2: Where are four-row cylindrical roller bearings commonly used?

A2: These bearings find extensive use in various industries, including manufacturing, mining, construction, power generation, and transportation. They are preferred in applications involving heavy machinery and equipment, where reliability and load-bearing capacity are crucial.

Q3: What are the key benefits of using four-row cylindrical roller bearings?

A3: The primary benefits include enhanced load capacity, reliability, reduced maintenance requirements, extended bearing life, lower energy consumption, and overall cost reduction. These bearings contribute significantly to improving industrial efficiency.

Q4: How do I select the right four-row cylindrical roller bearings for my application?

A4: When selecting these bearings, consider factors such as load capacity, speed ratings, and lubrication requirements. It's crucial to match the bearing specifications with the specific demands of your machinery and operating conditions.

Q5: What maintenance practices should be followed for these bearings?

A5: Proper lubrication is essential to reduce friction and dissipate heat. Regular inspections, lubrication checks, and monitoring of bearing temperature are necessary. Address any signs of abnormal wear or temperature spikes promptly to prevent costly breakdowns.

In conclusion, these frequently asked questions provide valuable insights into the world of four-row cylindrical roller bearings. Understanding the benefits, selection criteria, and maintenance practices associated with these bearings is essential for harnessing their potential in enhancing industrial efficiency. As you explore the possibilities of using these bearings in your applications, keep these FAQs in mind to make informed decisions that drive efficiency and productivity in your industry.

Mud pump bearings Turntable bearings Agricultural bearings Angular Contact Bearings Duplex Angular Contact Bearings Industrial bearings Iron and steel industry bearings Power transmission bearing Hydrostatic centripetal bearing Ball Thrust Bearings Papermaking Machinery bearings Agricultural machinery bearing McGILL bearing Rexroth pump assay Komatsu motor parts BOSCH Fuel injector Hitachi excavator parts Axial Piston Pumps Sauer Danfoss pump Eaton pump parts Nachi pump assay Linde pump Mining Construction Ball Bearings Linear Bearings vane pumps gear pumps inc piston pumps Thin-Section Ball Bearings Adapter Sleeves pressure valves gear reducer relief valves Mcgill Bearing Die & Mold Plain-Bearing Bushings FAG Bearing Singapore SKF bearing Accessories SKF bearing Housing SKF bearing shaft seals SKF Bearing units Bearing Distributors Inventory Oilfield mud pump bearings Heavy-Duty Shaker Screen Spherical Double row double row tapered roller bearings (inch series) Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Double inner double row tapered roller bearings inch Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row TNA Tapered Roller Bearings double-row TNASWE Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly four-row tapered roller Bearings • tQow – 2tdiw Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump parker vane pump Multi-Row Roller Bearings NTN Four Row Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings NTN SL Type Cylindrical Roller Bearings for Sheaves NTN Single Row Tapered Roller Bearings NTN Double Row Tapered Roller Bearings NTN Four Row Tapered Roller Bearings NTN Spherical Roller Bearings NTN Thrust Bearings NTN Bearings for special applications NTN DOUBLE-ROW CYLINDRICAL ROLLER BEARINGS NSK FULL-COMPLEMENT CYLINDRICAL ROLLER BEARINGS NSK SINGLE-ROW TAPERED ROLLER BEARINGS NSK YUKEN Piston pump DOUBLE-ROW TAPERED ROLLER BEARINGS NSK SPHERICAL ROLLER BEARINGS NSK SINGLE-DIRECTION THRUST BALL BEARINGS NSK CYLINDRICAL ROLLER THRUST BEARINGS NSK TAPERED ROLLER THRUST BEARINGS NSK SPHERICAL THRUST ROLLER BEARINGS NSK ROLLING BEARINGS FOR STEEL MILLS NSK SEALED-CLEAN FOUR-ROW TAPERED ROLLER BEARINGS NSK FOUR-ROW CYLINDRICAL ROLLER BEARINGS NSK DOUBLE-ROW TAPERED ROLLER BEARINGS NSK Roll Bearings for Mills NSK CROSSED-ROLLER BEARINGS NSK Ball Bearings NSK TAPERED ROLLER THRUST BEARINGS For Adjusting Screws NSK Roller Bearings NSK Thin Section Bearings Kaydon Double row double row tapered roller bearings (inch series) Double direction thrust tapered roller bearings Full complement Tapered roller Thrust bearing Thrust cylindrical roller bearings Thrust spherical roller bearings Sealed Four Row Tapered Roller Bearings Four row tapered roller bearings Double outer double row tapered roller bearings TDO double-row tapered roller bearings Single row tapered roller bearings inch Double inner double row tapered roller bearings TDI Single row tapered roller bearings Double inner double row tapered roller bearings inch Split spherical roller bearings Spherical roller bearing Four row cylindrical roller bearings Single row cylindrical roller bearings Full row of cylindrical roller bearings Double row cylindrical roller bearings Double row full complement cylindrical roller bearings Four point contact ball bearings Double row angular contact ball bearings Deep groove ball bearings ANGULAR CONTACT THRUST BALL BEARINGS TYPE TVL DTVL angular contact thrust ball bearing. TP thrust cylindrical roller bearing TPS thrust cylindrical roller bearing THRUST SPHERICAL ROLLER BEARINGS TYPES TSR-EJ AND TSR-EM TTHD THRUST TAPERED ROLLER BEARINGS TTHDFL thrust tapered roller bearing TTHDFLSA THRUST TAPERED ROLLER BEARINGS THRUST TAPERED ROLLER BEARINGS TYPES TTSP, TTSPS AND TTSPL THRUST TAPERED ROLLER BEARINGS – TYPES TTC, TTCS AND TTCL SCREWDOWN BEARINGS – TYPES TTHDSX/SV AND TTHDFLSX/SV THRUST TAPERED ROLLER BEARING TYPES TTDWK AND TTDFLK CROSSED ROLLER BEARINGS TXR Tapered Roller bearings double-row • Type TDO Tapered Roller bearings double-row TDI TDIT Tapered Roller Bearings double-row Spacer assemblies TTVS TTSP TTC TTCS TTCL tapered roller thrust BEARINGS Heavy-Duty Shaker Screen Spherical Roller Bearings Timken SPHERICAL ROLLER BEARINGS CYLINDRICAL ROLLER BEARINGS ONE-ROW METRIC ISO SERIES CYLINDRICAL ROLLER BEARINGS one-row STANDARD SERIES CYLINDRICAL ROLLER BEARINGS FULL-COMPLEMENT NCF CYLINDRICAL ROLLER BEARINGS TWO-Row Four-Row Cylindrical Roller Bearings CYLINDRICAL ROLLER BEARINGS HJ SERIES CYLINDRICAL ROLLER BEARINGS 5200 A5200 metric series HeavY-duty needle roller bearings four-row cylindrical roller Bearing assembly four-row cylindrical roller Bearing inner ring Outer assembly Timken Sealed roll neck Bearings four-row tapErEd rollEr BEaringS tQitS TnasWH TWo-roW TaPered roller bearings TdiT TnaT two-row tapErEd rollEr BEaringS tdik THrusT TaPered roller bearings TTdFlk, TTdW and TTdk bearings screwdown systems thrust tapered rollEr Bearings Thrust spherical roller bearing Mud pump bearings TOKYO-KEIKI piston pump TOKYO-KEIKI vane pump YUKEN vane pump DAIKIN piston pump DAIKIN vane pump DAIKIN Rotor pump VICKERS Piston pump Vickers vane pump VICKERS gear pump NACHI gear pump NACHI piston pump Rexroth A1VO Rexroth A10VSO Rexroth AA4VSO Rexroth A15VSO Rexroth AZPF parker PV piston pump parker PVP piston pump parker PAVC piston pump Main pump

Bearings 29496

Bearings 29496  Bearings 29272

Bearings 29272 Bearings 294/530

Bearings 294/530 Bearings 29438

Bearings 29438 Bearings 29288

Bearings 29288